焊接、锡焊设备

畅销物品

赞助赞助赞助赞助赞助赞助

Mild Steel Mig Welding Wire ALL SIZES - 0.7kg, 5kg, 15kg - 0.6, 0.8, 1.0 & 1.2

81.47元 至 493.34元500.85元 运费已售 272 件3M Speedglas 9100XX ADF Welding Lens Filter for 9100 - Auto Darkening

1,258.24元趋势价 1,267.89元eBay 通过机器学习模式取得过去 90 天的商品成交价,以决定此价格。或议价266.76元 运费Pine64 PINECIL V2 USB-C Portable Soldering Iron UK STOCK TS-100/101 COMPATIBLE

362.08元200.41元 运费已售 243 件White 0.8% Zirconiated Tig Welding Tungsten Electrode 1mm to 3.2mm for Aluminium

24.89元 至 353.03元126.82元 运费已售 100 件100ml kolophoniumfreies Flussmittel speziell für SMD löten Pinsel FLUX Lötwasser

88.43元19.33元 运费已售 189 件Glasfaser / Messing / Stahlborsten Stift Reinigungsstift Glasfaserradierer

35.64元 至 73.68元19.33元 运费20毫升通焊膏不锈钢液体焊接工具

13.70元原价: 14.42元或议价包邮8 Gramm Lötzinn Lötpaste in Spritze für SMD BGA Löten mit Flussmittel Solder PCB

83.00元19.33元 运费已售 655 件Flux AMTECH NC-559-ASM BGA PCB No-Clean limpia indispensable reballing.

45.50元10.09元 运费已售 218 件Soldering Iron Kit Set 80W Solder Wire Tips Cleaner Welding Irons Stand Tools UK

190.00元或议价包邮已售 584 件Parkside SMD Slim Cone 0.3mm Soldering Iron Tip PLS48 A1 B1 C1 D2 Lidl Aldi M4

45.17元21.63元 运费已售 1,900 件5 Stk Silberlot, 34% Silber, ummantelt, umhüllt, Fontargen AF319D BF Hartlot

155.28元或议价55.90元 运费已售 65 件Milwaukee Soldering Ceramic Heating Elements - for Milwaukee 12v Soldering Iron

94.02元原价: 117.52元55.58元 运费已售 132 件Messingdraht hart Ø 0.15-2.5mm Erodierdraht Messing CuZn37 blank

43.56元 至 1,569.24元395.18元 运费MIG Welding Contact Tips - M6 Thread (MB15 & MB25) - 0.6mm 0.8mm & 1.0mm

31.59元 至 543.03元532.99元 运费GENUINE PARWELD BZL CONTACT/ MIG EURO WELDING TIPS 0.6, 0.8, 1.0, 1.2mm Next Day

35.12元 至 544.57元126.64元 运费Piezo spark ignitor ignition SISTOTEC butane torch repair

54.31元45.26元 运费13 人正在追踪Solder Soldering Wire Premium 0.8mm 60/40 Rosin Flux Core Electronics PCB Repair

26.88元 至 542.85元126.00元 运费已售 245 件Kohlefaserpinsel für WIG Brenner 17er, 18er u. 26er - 50mm nutzbar PTFE Hülse

107.53元或议价45.03元 运费已售 524 件CASTOLIN PORTABLE GAS LEAD WELDING-BRAZING-PLUMBING-ROOFING-MINI PORTAPACK KIT

3000c - ANTI FLASHBACK - READY TO USE995.64元373.67元 运费Axrayser 激光喷嘴单层双层 D32 毫米镀铬 全新 适用于 Raytools

25.58元 至 36.16元包邮10 x Wolfram Elektroden WIG Nadeln 1,0/1,6/2,4/3,2 x 175 mm

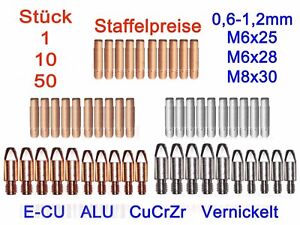

WL15, WS02, WL10, WC20, WZ08, WP00, WL20, WT20, WT3038.74元 至 225.08元54.35元 运费Stromdüse M6/M8 E-Cu ALU Kontaktspitze Kontaktrohr MB MD MIG/MAG Stromdüsen

7.76元 至 482.29元62.11元 运费已售 54 件WP-17FV Tig 焊接手电 完整灵活 头部 适合 空气冷却 手电筒 10 英尺

173.93元或议价包邮41 人正在追踪Lötzubehör Lötzinn Lötfett Kolophonium Lötspitzen Abstreifer Löt Zubehör Fett

33.85元 至 100.08元19.33元 运费已售 544 件Hakko A5044 陶瓷过滤器 10 包 适用于 FR-310/FR-4103(FR-410, FR-701, FR-702) JP

85.52元趋势价 88.13元eBay 通过机器学习模式取得过去 90 天的商品成交价,以决定此价格。包邮已售 76 件WELDGAS PORTABLE GAS LEAD WELDING-BRAZING-PLUMBING-ROOFING-MINI PORTAPACK KIT

ON OFFER! UNTIL THE END OF FED !1,357.72元677.00元 运费95 人正在追踪E316 Stainless Steel ARC Welding Rods Electrodes 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm

19.01元 至 712.85元316.82元 运费31Pcs TIG Welding Torch Stubby Gas Lens Pyrex Glass Cup Kit Fits for WP-17/26 SL

235.42元或议价70.65元 运费已售 39 件Parweld XR938H grey large view 5-13 auto welding & grinding helmet TRUE COLOUR

570.28元497.86元 运费已售 1,232 件Weld Right® ER316L Stainless Steel Arc Welding Electrodes Rod 1.6-3.2mm 10-10...

72.33元 至 389.15元413.77元 运费Netzteil Beizgerät Signiergerät Edelstahl/Stahl Reinigen Signieren 12V 25A 300VA

2,717.36元247.67元 运费仅剩 1 件!Raptor Pro Tungsten Grinder Sharpener TIG Welding (Top Section Only)

905.21元284.33元 运费42 人正在追踪WorkZone Soldering Iron Tip Replacement HS-060A-2 WWS-SST60 WWS-S Aldi Lidl M4

45.17元21.63元 运费已售 673 件Solder Fume Extractor Fan Activated Carbon Filter USB Powered UK Seller

90.43元 至 135.69元47.07元 运费已售 107 件10ML Soldering Flux Paste Tacky Solder Flux Pneumatic Dispenser Halogen Free Au

40.04元原价: 42.16元或议价46.87元 运费PP/EPDM plastic welding rods 3mm triangle shape, black pack of 10-60 pieces

36.12元 至 101.38元126.73元 运费已售 886 件新物品刊登3M Speedglas G5-01 TW Welding Filter Lens

1,765.15元575.26元 运费1 x Round Cup Flint Lighter Gas Welding Cutting Spark Sparker Fire Starter Flame

26.70元45.26元 运费已售 1,184 件0.5mm silver solder wire 6ft long. select pack size

51.51元 至 409.61元127.82元 运费已售 2,058 件Lötpaste Flussmittel RMA-223 Flux SMD BGA Lötfett 10ml

54.27元或议价62.03元 运费已售 106 件Castolin 1020 XFC Silberlot 57% Silber 2 mm!!! Silberhartlot Flussmittelumhüllt

77.64元或议价55.90元 运费已售 159 件Soldering iron tip cleaner refresher oxide paste scrub tinner BST 511 513 8g 30g

73.14元54.22元 运费已售 42 件ATTEN ST-862D 喷嘴适配器转换器适配器适用于所有 850 系列喷嘴焊接

101.24元或议价8.99元 运费仅剩 1 件!WorkZone SMD Bevel Soldering Iron Tip Replace HS-060A-2 WWS-SST60 Aldi Lidl M4

45.17元21.63元 运费已售 244 件1,6 mm 0,1 kg 308 L V2A 1.4316 Edelstahl INOX Elektrode Stabelektroden NIRO 308L

41.61元趋势价 42.03元eBay 通过机器学习模式取得过去 90 天的商品成交价,以决定此价格。62.11元 运费已售 99 件Flux AMTECH NC-559-ASM BGA PCB No-Clean soldadura limpia indispensable reballing

45.81元10.87元 运费已售 41 件Parkside SMD Chisel Soldering Iron Tip Replacement PLS48 A1 B1 C1 D2 Lidl Aldi

45.17元21.63元 运费已售 804 件100mm 115mm 125mm Tungsten Electrode Sharpener Grinder disc

108.53元 至 153.79元36.21元 运费已售 75 件0.031 - 银焊料 5% 银 8 英尺 - (96) 长度 KESTER - 免费 FLUX 包

43.41元12.32元 运费0.015 - 银焊料 3% 银色 100 英寸长 KESTER--低熔体 + 免费通量

38.34元或议价20.29元 运费已售 240 件8000W Mini-Punktschweißmaschine DIY für 18650 Li-ion-Akku-Punktschweißgerät Kit

46.51元 至 545.72元15.45元 运费59 人正在追踪Gasanzünder Walzenfeile Bügelanzünder Autogen Anzünder Zündstein Feuerstein 3x20

23.21元 至 34.01元77.64元 运费已售 965 件Quicko T12-942 OLED 数字焊接站 + 手柄熨斗头焊接套件

260.83元或议价36.24元 运费已售 52 件ARC welding rods. Electrodes. Mild steel. 1.6mm - 4.0mm E6013 General purpose.

19.01元 至 316.82元362.08元 运费已售 891 件140 Amp Portable Compact Inverter IGBT Welder

Same Day Dispatch (3PM) ✅ Free Delivery* Avl ✅ 2 Yr War398.20元趋势价 402.72元eBay 通过机器学习模式取得过去 90 天的商品成交价,以决定此价格。522.30元 运费已售 680 件

优秀评级

Kiswel K-NGS0302 AWS A5.20 E71T-GS Gasless-Flux Shielded Cored Welding Wire97% 同意 - Would recommend123.13元 全新

Kiswel K-NGS0302 AWS A5.20 E71T-GS Gasless-Flux Shielded Cored Welding Wire97% 同意 - Would recommend123.13元 全新 WeldingCity 169715 1/2" Gas Nozzle for Miller and Hobart MIG Welding Guns - Pack of 5100% 同意 - Good value140.52元 全新

WeldingCity 169715 1/2" Gas Nozzle for Miller and Hobart MIG Welding Guns - Pack of 5100% 同意 - Good value140.52元 全新

Weldingcity 5-lb E6013 3/32" Stick Welding Electrode Mild Steel Rod100% 同意 - Would recommend181.11元 全新

Weldingcity 5-lb E6013 3/32" Stick Welding Electrode Mild Steel Rod100% 同意 - Would recommend181.11元 全新